Commercial Aircraft Maintenance - The popularity of narrowbody aircraft is also on the rise. For years, the narrowbody share of the total fleet has increased as the improving range capability and attractive seat mile efficiency of the class have made the aircraft the choice of low-cost carriers.

This trend is expected to continue as more airlines align fleets to the demand realities of COVID-19. International travel — which accounts for the bulk of long-haul — evaporated in the early days of COVID-19 and continues to be hard-hit, which has had implications for widebodies.

Commercial Aircraft Maintenance

Over the last year, nations around the world have been tightly regulating cross-border travel in an effort to keep out or at least contain the pandemic. Border closings and sudden requirements to quarantine for 14 days have discouraged travel between countries, with passengers fearful of being stranded or unable to get home.

How Do I Obtain Permission To Take The Amt Knowledge Test?

Under a new executive order from President Joe Biden, travelers entering the United States must provide proof of a recent negative COVID-19 test prior to entry — a requirement that already exists in some other countries.

That means cash preservation will remain a top priority for airlines, which is not good news for aerospace manufacturers and maintenance, repair, and overhaul (MRO) service providers. In 2020, COVID-related pressure on airline cash flow and reduced demand for air travel led global carriers to put thousands of aircraft into storage, retire twice as many as normal, convert some for carrying cargo, and cancel or defer some deliveries of new planes

. It’s no exaggeration to say that modern commercial aviation has never faced such a long list of challenges as COVID-19 has created. It will likely take several years to adjust the fleet to new realities, and even then, the industry will not regain over the next 10 years all that it has lost with the pandemic.

In contrast, North America — a region that has not contained the virus yet — has restored only 46 percent. Even so, the region's aircraft are seeing very low utilization, given the uncertain conditions and sporadic demand.

As A Foreign National What Do I Need To Show To The Faa In Order To Take The Aviation Maintenance Technician Tests?

Secure .gov websites use HTTPS A lock ( LockA locked padlock ) or https:// means you've safely connected to the .gov website. Share sensitive information only on official, secure websites. Given that some regions of the world have been emerging from the COVID-19 curse sooner than others, their airlines have been more aggressive in restoring planes to service.

For instance, in response to rising domestic air travel numbers, Chinese airlines have put back into service 91 percent of the aircraft they sent to storage, meaning the fleet is quickly approaching pre-COVID levels. But while demand has revived, there are new viral outbreaks that the Chinese government will have to contain to keep business growing.

AMTs hold highly-transferable skills that can be used in a broad-range of industries; career opportunities in the aviation sector include employment at airlines, fixed-base operators, manufacturers, repair stations, aviation maintenance schools and in business or general aviation.

Specialty fields include avionics, balloons and airships, rotorcraft, and unmanned aircraft systems. A. If you present evidence, only in the form of documented practical experience in maintaining an airframe and/or a powerplant, you will need to go to an FSDO, and present your completed FAA Form 8610-2, Airman Certificate and/or Rating Application

What Is The Process For Obtaining An Aviation Mechanic Certificate Based On Previous Experience?

, to an ASI, to receive authorization to test. If you are a graduate of an AMTS with an FAA-approved curriculum, you may present your graduation certificate as eligibility to take the AMT knowledge tests. Videoconferencing and teleconferencing have become attractive substitutes that allow companies to cut travel budgets, particularly for intracompany trips.

COVID-19 has also forced many business conferences and trade shows to go virtual or be canceled entirely, eliminating another reason for executive travel. While most of this travel will eventually return as more people get COVID-19 vaccinations, it is unlikely to recover fully over the midterm.

Bottom line: The outlook is better with 2020 spending on maintenance, repair, and overhaul now expected to reach $50.3 billion, which represents 55 percent of the $91.2 billion that was expected pre-COVID. In May, the outlook for spending was only $42.7 billion.

A. If you are a foreign applicant located in the U.S., you need to meet the same requirements as a citizen of the U.S. in order to apply for the AMT tests. This also applies if you travel to the U.S.

Am I Required To Have An Aviation Mechanic Certificate To Get A Job As An Airline Mechanic?

for the purpose of taking the AMT tests. If you apply based on experience only, you must have verifiable experience in 50 percent of the subject areas listed for the rating sought (refer to 14 CFR part 147 appendices B, C, and D) in order to be eligible.

It is difficult to overstate the effect of the COVID-19 pandemic on commercial aviation. In the months since the new strain of coronavirus that causes COVID-19 first emerged, passenger air travel has come to a near standstill as a result of the need for social distancing and international travel restrictions to contain its rapid spread.

Air carriers around the world are facing extreme financial pressures and are cutting capacity at unparalleled rates in the absence of meaningful passenger demand. Some airlines have shut down completely, a portion of these may never return.

There’s an effort to reopen the economy and Transportation Security Administration statistics are showing a slight upward move in the number of travelers screened at airports, but ticket sales took a hit in late June after COVID-19 cases surged in the United States.

I Worked Hours A Day Days A Week For A Total Of Hours As An Ap Mechanic Apprentice During The Past Year Since This Time Is Equal To The Number Of Hours Accumulated By Working Hours A Week For Months Does This Comparable Mechanic Experience Time Qualify Me To Take The Amt Knowledge Tests?

A. You will need to make an appointment to visit a FSDO. Bring two completed FAA Form 8610-2 applications, and all documentary evidence of your experience for the ASI to evaluate. If the ASI deems your documentation adequate, you will receive authorization to take the AMT knowledge tests.

After you have passed the knowledge tests (with a score of 70%, or greater), you will need to make an appointment with a DME. Give your knowledge test results to the DME, who will then administer the oral and practical (O&P) portions of the testing process.

After you have satisfactorily completed the O&P portions of the testing process, you will receive a Temporary Mechanic Certificate. A. No, possession of an Aviation Mechanic certificate, for employment by an air carrier, is not an FAA regulatory requirement.

However, air carriers often call for an Aviation Mechanic certificate as a hiring requirement. If you have one, this could lead to enhanced opportunities and higher wages throughout your career. A. No, 14 CFR part 65, Certification: Airmen Other Than Flight Crewmembers, Subpart D - Mechanics, does not provide for anything less than 18 months of practical experience for issuance of an Aviation Mechanic certificate, with a single rating.

Is It True That I May Test At No Cost To Me If I Qualify Under The Memorandum Of Agreement Moa Between The Faa And The Joint Service Aviation Maintenance Technician Certification Council Jsamtcc?

Likewise, part 65 does not provide for anything less than 30 months of practical experience, concurrently performing the duties appropriate to both the Airframe and Powerplant ratings, for an A&P certificate. Other aerospace revenue may also be in jeopardy.

The early retirement of planes may reduce aerospace sales of new parts because of increased competition from the surge in supply of used components and green-time engines harvested from retired aircraft. It will take as much as three years to work through the excess of used serviceable material.

A. Yes, if you are an eligible individual, within one of the following groups, you may take your AMT knowledge tests at no cost: active-duty, guard, and reserve component personnel of all U.S. BOSs; dependents of active-duty, guard, and reserve component personnel of all U.S.

BOSs; U.S. Military retirees; DoD civilians; and Department of Homeland Security (DHS) civilians. A. No, even if you are issued a similar certificate or license by a country other than the U.S., you must still meet the FAA eligibility requirements and pass the required tests to be issued an FAA Aviation Mechanic certificate.

I Hold An Aircraft Maintenance License Issued By A Country Other Than The Us May I Be Granted An Faa Aviation Mechanic Certificate Based On My Aircraft Maintenance License?

This year's research focuses on the aviation industry's recovery from COVID-19, subsequent growth and related trends affecting aftermarket demand, maintenance costs, technology, and labor supply after a devastating 2020. The outlook reveals significant challenges the industry faces as it develops and expands its

recovery and rebound plans. To supplement the 2020-2030 Global Fleet & MRO Market Forecast Update, our COVID-19 impact interactive dashboard provides users with the ability to explore the near-term impact of COVID-19 on MRO demand in a deeper fashion.

Both dashboard views include a summary table that quantifies the updated MRO forecast and the corresponding impact. Contributing to the decline in international long-haul travel has been the fall in business travel, the most profitable category for airlines.

This is especially true on long-haul flights, on which executives often opt for premium seating. Given the inventory backlog of new planes that are built but undelivered or still not sold, more aircraft will be delivered to airlines over the next several years than will be produced by aerospace manufacturers.

What Documents Do I Need To Provide For Asi Evaluation Prior To Taking The Knowledge Test?

While production and deliveries are closely aligned in normal years, the imbalance reflects conflicting pressures on airframe manufacturers to balance the realities of lower market demand with the needs of key suppliers to maintain sufficient production.

In contrast, widebody aircraft production has seen a significant decline due to COVID-19's impact on long-haul travel demand. Over the forecast period, we expect widebody production to be as much as 40 percent below pre-COVID expectations unless there's a faster-than-expected recovery in long-haul routes.

2021 is unlikely to be much different. Except for airlines in China, where domestic travel returned to pre-pandemic levels by November 2020, global carriers will still burn millions in cash daily for much of the year — but probably not all of it.

Some will face the unsettling prospect of restructuring and consolidation. Losses in the tens of billions of dollars are expected again this year, although the industry will suffer less than half of the hit it sustained the first year of COVID-19.

How Do I Test For An Faa Aviation Mechanic Certificate?

A. All Aviation Mechanic knowledge test applicants need to provide appropriate proof of identification to the ASI. You should also present documentary evidence from former and current employers indicating your length and type of experience. If you graduated from an AMTS, you should present your graduation certificate.

If you were an Aviation Mechanic in the U.S. Military, you should present your: DD Form 214, including information on your length of service, the schools you attended, the MOS codes you worked under, and the time worked for each code;

your personal evaluation records; and a letter from either your Executive Officer or Classification Officer. The dashboard is amended weekly based on new developments and insights and compares the original MRO forecast, released in February 2020, to an adjusted forecast baseline.

As a result of new information to include more airline capacity reductions and revised OEM production announcements, the adjusted forecast baseline in the dashboard may vary from the baseline in the article above as data have changed since the article was published.

Do I Need Any Other Certificate To Work On Avionics Equipment?

Deliveries of narrowbodies in 2021 will also be bolstered by decisions by the Federal Aviation Administration and the European Union Aviation Safety Agency to recertify the Boeing 737 MAX for commercial service. More than 20 737s have already made it back into carrier fleets since the recertification, but there are 400 to 450 more MAX aircraft, built in 2020, that are sitting in Boeing's inventory undelivered or not sold.

In addition, the number of narrowbodies in the fleet will be expanded by the almost 400 737s that airlines have had in storage since the plane's grounding in March 2019. While forecasts for narrowbody production are 40 percent below 2018 levels for 2021, we expect the aircraft class to recover to within 10 percent of our original pre-COVID projections for the final years of the forecast period.

One bright spot has been sales of A321LR, which remain strong even in the face of the pandemic. The aircraft offers sufficient range to serve routes that were previously flown with Boeing 757s or widebody aircraft, as well as providing airlines increased flexibility in their scheduling.

But with all these planes moving back into service, where's the demand. Based on Oliver Wyman modeling, domestic air travel won't match 2019 levels until mid-2022. International travel is not expected to match 2019 totals until mid-2023.

If I Have A Physical Or Medical Disability Will It Disqualify Me From Getting An Aviation Mechanic Certificate?

A. This list of required steps applies to you, whether or not you are a U.S. citizen. citizen. If you are issued a similar certificate or license by a country other than the U.S., you must still meet the FAA eligibility requirements, and pass the required tests, to be issued an FAA Aviation Mechanic certificate:

Are you interested in a career that provides well-paid opportunities and ensures the safety of the flying public? FAA-certified Aviation Maintenance Technicians (AMT) work in highly-technical specialty occupations involving the continued operational safety of products and articles, keeping U.S.-registered aircraft operating safely and efficiently.

“My instructors were knowledgeable about the subjects, and able to give me tips and tricks beyond the curriculum to improve my understanding of the material. With their support and National Aviation Academy’s curriculum I was able to, not only get my certifications, but secure employment!”

A. No, unless your disability affects the eligibility requirements. If your disability has such an impact, contact your local FAA Flight Standards District Office (FSDO) for more information. (Note: Some employers have established physical or medical requirements for employment as an Aviation Mechanic with their organization.)

If I Fail Any Part Of The Written Or Oral And Practical Tests How Soon Can I Apply For A Retest?

maintenance of aircraft, aircraft maintenance articles, aircraft maintenance facility requirements, airplanes maintenance, aircraft maintenance training program, cae aircraft maintenance training, commercial aircraft maintenance checks, types of aircraft maintenance

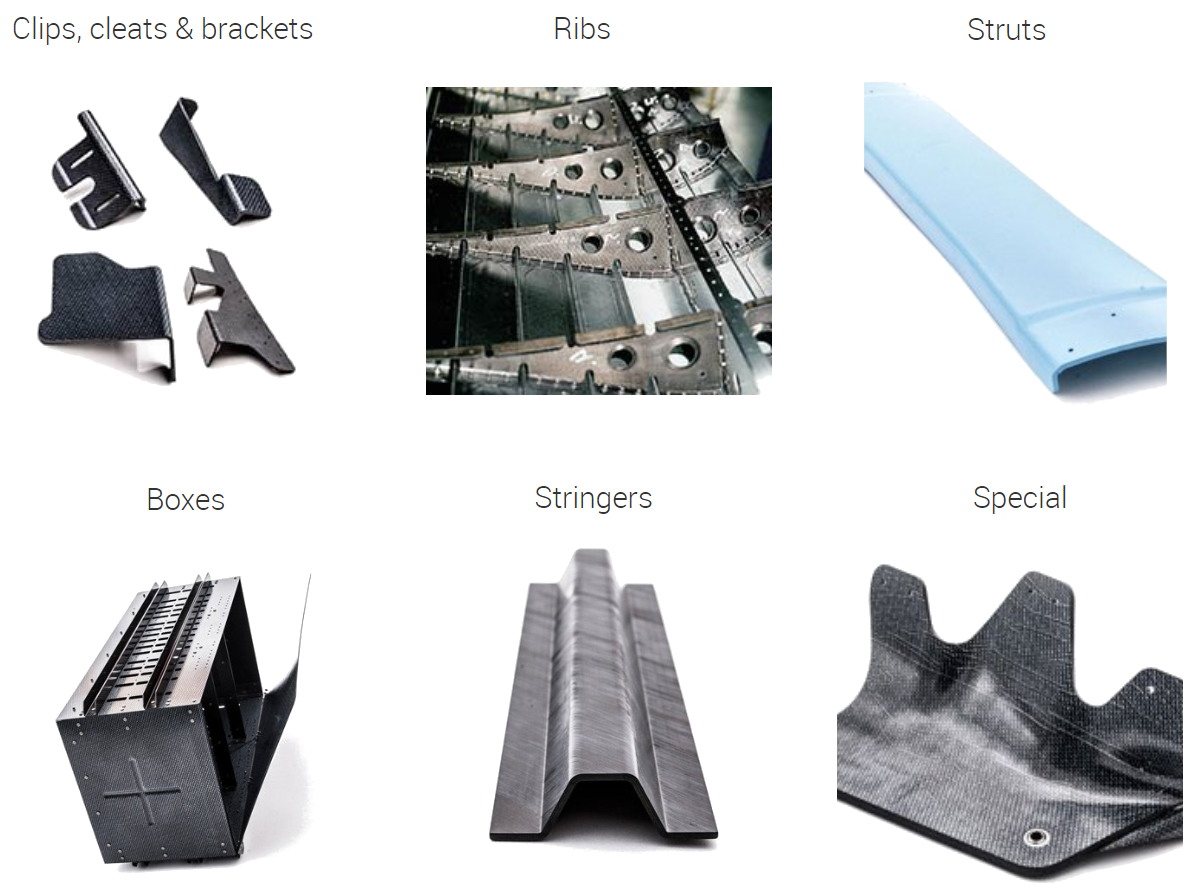

![Pdf] Low-Cost Composite Materials And Structures For Aircraft Applications | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/1672382321c448831a5e872fef2e1e325393324a/7-Figure7-1.png)