Composites In Aircraft - The aerospace industry and manufacturers' unrelenting passion to enhance the performance of commercial and military aircraft is constantly driving the development of improved high performance structural materials. Composite materials are one such class of materials that play a significant role

role in current and future aerospace components. Composite materials are particularly attractive to aviation and aerospace applications because of their exceptional strength- and stiffness-to-density ratios and superior physical properties. Within the facility, the NCC has installed two huge industrial robots that automate the wing production process.

Composites In Aircraft

Weighing 45,000kg and 24,000kg respectively, the robots measure, cut, lift and place pieces of carbon fiber fabric ('plies') with millimetric accuracy. They can also lay 5m wide strips of composite material, up to 20m long, in one precise movement.

The project will develop training courses related to advanced digital engineering, with the aim of increasing the skills and retraining those in the current workforce. It will also engage with schools, particularly in less affluent parts of the West of England, with the aim to reach 1,000 children and inspire them to pursue a career in digital engineering.

Other technologies within the facility include a giant circular braider (see below), the largest of its kind in Europe, which automatically weaves up to 288 individual strands of high-strength carbon fiber to create hollow 3D shapes (or geometries), for products such

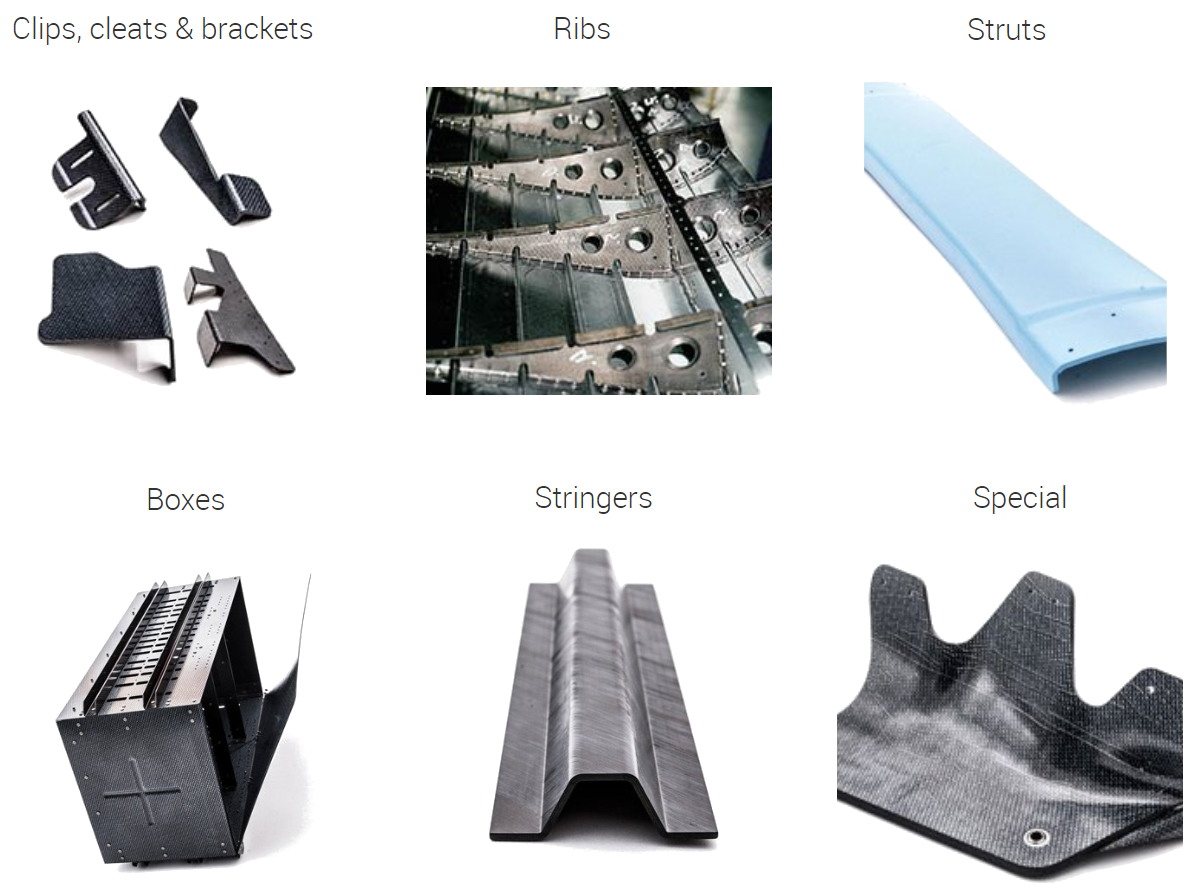

as pipes or aircraft propellers. Complex shapes Another advantage of composite materials is that, generally speaking, they can be formed into more complex shapes than their metallic counterparts. This not only reduces the number of parts making up a given component,

but also reduces the need for fasteners and joints, the advantages of which are twofold: fasteners and joints may be the weak points of A component 'a bolt needs a hole which is a stress concentration

and therefore a potential crack-initiation site, and fewer fasteners and joints can mean a shorter assembly time. "The world faces unprecedented challenges which will require step changes in how society uses resources. DETI will bring together leading companies and tech disruptors to create the design and digital engineering of the future.

It will help cement the UK's world-leading position as an engineering nation, helping to overcome the world's most complex challenges,” said Oldfield. Funded, in part, by the Aerospace Technology Institute (ATI), in collaboration with the Local Enterprise Partnership and the High-Value Manufacturing Catapult, the program has brought composites into the digital age, increased production rates and quality while improving efficiency and reducing costs.

![Pdf] Low-Cost Composite Materials And Structures For Aircraft Applications | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/1672382321c448831a5e872fef2e1e325393324a/7-Figure7-1.png)

, its members have said. More than 15,000 people visited the Aerospace Engineering Blog last month to learn something new about aerospace engineering. To get started, check out some of our most interesting posts, listen to the podcast or subscribe to our monthly newsletter.

"With the most advanced manufacturing facility in Europe, we truly have an unrivaled world-class capability," said Richard Oldfield, chief executive of the NCC when launching this new phase. "The investment in 10 new world-leading composites capabilities will enable us to develop the wings and engines for the aircraft of the future, work on technologies that will define the way we produce and store energy and transform the way we build infrastructure."

The only two-ring braider in the UK, the NCC braider (pictured above) comprises 288 and 192 spools and is more than twice as flexible as a single-ring braider. The two rings and a 10m long gantry enable its operators to braid complex circular, rectangular and convex sections, in the widest possible range from 50mm to 800mm equivalent diameter.

The braider is also capable of a very high deposition rate: up to 50kg/h. In an automated process, however, Giddings thinks that manufacturers have a better chance of getting the process right the first time around, which therefore means they won't scrap components.

"There's nothing less efficient than deciding to put something in the bin," he adds. "That's a big drive for us." DETI is a research, innovation and skills initiative – a collaboration of industry and academic partners led by the NCC – which sets out to develop and accelerate digital engineering across multiple industry sectors to benefit future generations of engineers and engineering products, and to help tackle global

challenges. To make the wing, design engineers use digital modeling and simulation, analyzing thousands of possible configurations to create a digital pattern book of the layers or 'plies'. For a single wing skin with 150 plies, there could be up to 14,000 possible combinations of cutting and laying, according to the NCC.

The global market for composites is predicted to be worth $105.8bn (£82.8bn) in 2020 and growing at 6.5 per year. In the UK alone, the value of composites is expected to reach £12.5bn by 2030 as manufacturers seek to make products lighter, stronger and more durable.

According to the NCC, the Bristol-based center ensures that Britain is at the forefront of this fast-growing sector. Giddings said this process may look simple, but to execute it remains a challenge. "These fabrics are so delicate that if you gently place your hand on them, you leave a handprint on them," he explains.

"People aren't really able to lift them, as they deform and sag as they are incredibly flexible." So-called 'conventional' metallic materials and their derivatives continue to be developed and improved to offer ever-increasing performance, and there is no doubt that they have a fundamental role in aerospace

structures and the myriad applications in which they are employed. At the same time, there is little doubt that the considerable benefits offered by composites have yet to be fully exploited and as knowledge and understanding grow, composite materials will play an increasing

significant role. This role will expand not only as a result of improved material performance, but also as human ingenuity finds more and diverse Areas where composite materials can be beneficially employed and leveraged. Once the pieces of fabric have been cut into a shape they can be filed in drawers or directly placed onto a tool in two ways.

The FibreFORM tool (see above) has 270 suction cups mounted on flexible 'spline', each able to position and provide suction on command. It can pick up a piece of material and carefully manipulate it into a 3D shape and then place it on a specially shaped tool and repeat the process.

Its FibreROLL tool (pictured below) then rolls up the ply and lays it across the shaped tool surface. The UK's National Composites Center (NCC) in Bristol has opened a new research and development facility that aims to harness the power of new digital technologies - one of which has the potential to build the aircraft wings of the future.

Composite advantages In addition to the main benefit of reduced weight and formability, Composite materials offer better resistance to some forms of corrosion than metal alloys and good resistance to fatigue 'a crack in the brittle fiber is halted, temporarily at least, when it meets the

tougher resin matrix. Back in December 2018, the NCC had secured funding for the £36.7m iCAP (Digital Capability Acquisition) programme, under which ten new technologies, tailor-made to the NCC's specifications, were installed within the facility in order to speed up the development of new

processes for all forms of composite manufacturing. At an event at the NCC on 28 February, it was announced that the NCC and other businesses in the region around Bristol are now embarking on another programme, which aims to put the West of England on the map for manufacturing and aspires to revolutionise the region's

advanced digital engineering sector. Particulate composites CFRP and GFRP are fibrous composite materials; another category of Composite materials are particulate composites. Metal matrix composites (MMC) that are currently being developed for the aviation and aerospace industry are examples of particulate composites and consist, usually,

of non-metallic particles in a metallic matrix; for instance silicon Carbide particles combined with aluminum alloy. Especially due to the uncertainty of correctly modeling the complicated failure modes, engineers have tended to revert to a "black" aluminum approach that has inhibited the full exploitation of composite materials in terms of potential weight savings.

However, the ongoing research activities into advanced composites and increasing teaching in higher education will hope to resolve these issues in the near future. Regarding the process of the Overmoulder, a composite sheet is melted and formed, and then the thermoplastic polymer is injected over the surface in this highly automated process, that can achieve rapid cycle production of less than 5 minutes with potential for under 60-second cycle.

times for some parts. According to the NCC, this process combines the structural benefit of a long-fibre reinforced composite sheet with the speed and geometric complexity of injection moulding. In response to this issue, NCC engineers have commissioned two 3m-high robots that work in unison, on either side of the component, to beam ultrasound down high-pressure water jets.

The system then measures the time taken for sound to travel through the part, alerting operators to any anomalies. This, therefore, ensures the components meet safety regulations. Giddings also said the NCC is looking at ways to be less energy-intensive in its manufacturing process, for example, in its industrial oven.

"We're trying to tune where we put heat into different parts of a structure," he explains. "So if something has a hotter material, and it's going to be quite slow to heat up, we can concentrate the energy in that area, whereas for other parts of the component where it doesn't need that much heat to make it the same

temperature, we don't put that much heat into it.” Therefore, they are balancing off the energy they use to achieve the result and end product they need – not overheating or underheating certain parts. – The failure modes in composites are very diverse and include fiber failure, resin failure, fiber/matrix debonding, delaminations etc., which generally increases the analytical workload.

Often these failure modes are related such that it can be difficult to accurately predict the failure load. Two years on, Peter Giddings, chief engineer of the iCAP program at the NCC, says the experience has been brilliant.

"It's been really developmental - both as a business where we were a good research center, but a small one," he told E&T, "and we've had a massive amount of faith from the funding bodies, and support from them, and

some really strong relationships with customers.” The NCC aspires to become more sustainable in its manufacturing process, and Giddings believes that making such processes automated will help limit a manufacturer's climate impact. "The best way to mitigate the impact from climate is to make fewer mistakes [in the process]," he explains.

“Ultimately for many manufacturing processes, you have to create a lot of force, making things quite hot; both of those require a lot of energy – and you don’t want to be doing that again.” The A380 is about 20 to 22 percent composites by weight and also

makes extensive use of GLARE (glass-fibre-reinforced aluminum alloy), which features in the front fairing, upper fuselage shells, crown and side panels, and the upper sections of the forward and aft upper fuselage. GLARE laminates are made up of four or more 0.38 mm (0.015 inch)

thick sheets of aluminum alloy and glass fiber resin bond film. GLARE offers weight savings of between 15 and 30 percent over aluminum alloy along with very good fatigue resistance. The top and bottom skin panels

of the A380 and the front, center and rear spars contain CFRP, which is also used for the rear pressure bulkhead, the upper deck floor beams, and for the ailerons, spoilers, and outer flaps. The belly fairing

consists of about 100 composite honeycomb panels. Composite materials are used extensively in the Eurofighter: the Wing skins, forward fuselage, flaperons and rudder all make use of composites. Toughened epoxy skins constitute about 75 percent of the

exterior area In total, about 40 percent of the structural weight of the Eurofighter is carbon-fibre-reinforced composite material. Other European fighters typically feature between about 20 and 25 percent composites by weight: 26 percent for Dassault's Rafael and 20 to 25 percent for the

Saab Gripen and the EADS Mako. However, the NCC's partners within the aerospace industry had given them the challenge of creating a method of making this process ten times faster – wanting them to work with dry fabrics to infuse the resin at a later stage.

DETI is not a new building but will use existing facilities and assets at the NCC and another crucial partner in the collaboration, the Center for Modeling and Simulation (CFMS) at the Bristol and Bath Science Park, to undertake its research, innovation and skills initiatives.

. It also aims to bring together the wealth of specialist expertise from around the region and harnesses it to maximize opportunities for a better future. It was not until the invention of phenolic resin in 1909 that composites took off in aircraft.

The most famous example was the deHavilland Albatross transport aircraft manufactured from a ply-balsa-ply sandwich fuselage construction, which was later developed into the deHavilland Mosquito multi-role combat aircraft for WWII. The large-scale wooden construction made the Mosquito extremely light, fast and agile.

Furthermore, the Mosquito was cheaper than its metallic counterparts and allowed highly skilled carpenters from all over the UK to be contracted to help with the war effort. One disadvantage of early phenolic resins was their inability to cope with hot-wet conditions such that the Mosquito became notorious for disintegrating in mid-air in the Pacific War arena.

Furthermore, Giddings said some of the processes the NCC uses are suitable for the reuse of recycled products. "The equipment is enabled to take recycled materials wherever possible," he says. "We've got some other big programs in the business looking at how we recycle materials."

composite materials in aircraft, what are aircraft composite fibers, composite materials used in aircraft, aircraft composite manufacturing, airplane composites, airplane composite materials, composite aircraft technology, composite materials for aircraft structures